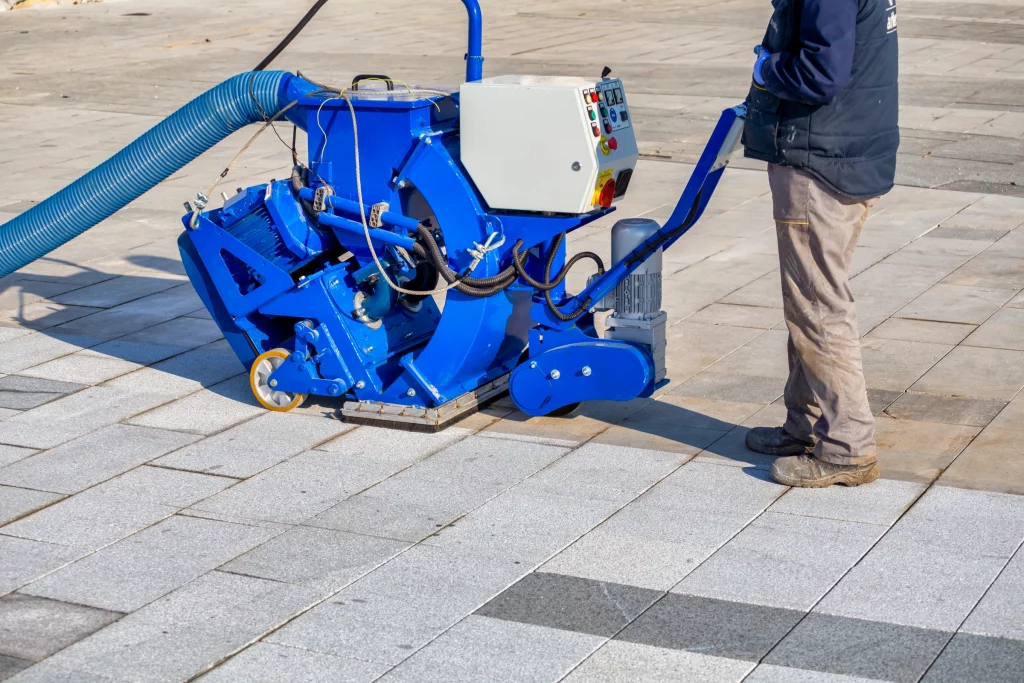

What is Shot Blasting?

Shot blasting is a powerful and efficient method used for surface preparation, where tiny steel balls or shots are propelled at high velocity onto a floor surface. This process effectively removes contaminants, old coatings, and creates a roughened texture, making it ideal for the subsequent application of epoxy coatings or other floor treatments. The result is a clean, profiled surface that ensures optimal adhesion for coatings.