You’ve just finished applying epoxy flooring in your garage, and it looks amazing. But now comes the waiting game, and you’re probably wondering: when can I actually use my garage again?

It’s a fair question. After all, the floor might look ready after just a few hours, but looks can be deceiving. Understanding how long epoxy takes to cure helps you avoid mistakes that could mess up your beautiful new floor.

Here’s the good news: while epoxy does need time to fully harden, you don’t have to wait weeks before using your garage. The process happens in stages, and each stage opens up new possibilities for what you can do on your floor.

In this guide, we’ll walk you through everything you need to know about epoxy curing times. Whether you’re doing it yourself or working with pros like GLI Epoxy Flooring, knowing what to expect makes the whole process less stressful.

Understanding the Difference Between Drying and Curing

Before we get into timelines, let’s clear something up. Epoxy doesn’t actually “dry” the way paint does. Instead, it goes through a process called curing.

What Does “Dry to Touch” Really Mean

When paint dries, water or solvents evaporate into the air. Simple enough, right? But epoxy flooring north york works differently. When you mix the two parts together, a chemical reaction starts. The liquid transforms into a solid through this reaction, not through evaporation.

So when your floor feels dry to the touch after a few hours, it’s really just the surface that’s hardened up. Underneath, the chemical reaction is still happening. Think of it like a cake in the oven—just because the top looks done doesn’t mean the middle is ready.

This matters because walking on a floor that feels dry might still damage the coating underneath. The surface might be solid, but it’s still vulnerable below.

The Science Behind Complete Epoxy Curing

The chemical reaction that hardens epoxy creates heat. You might notice your floor feeling warm during the first day—that’s completely normal. The reaction links molecules together into a strong network, kind of like building a chain-link fence at the molecular level.

This network gives epoxy flooring its strength and durability. But building it takes time—more time than most people expect. The process happens quickly at first, then slows down over the following days and weeks. Even after your floor seems completely hard, it’s still getting stronger at the microscopic level.

Initial Set Time: The First 24 Hours

The first day is the most important time for your new floor. During these first 24 hours, your epoxy flooring goes from liquid to solid, but it’s pretty delicate.

Walking on Freshly Applied Epoxy Flooring

Most epoxies feel dry to the touch after about 8 to 12 hours at normal room temperature (around 70°F). But “dry to touch” doesn’t mean “ready for feet.”

The general rule? Wait a full 24 hours before walking on your floor, even just to peek at how it looks. If you absolutely need to walk on it sooner, wear socks and step very carefully. No shoes, no twisting motions, no dragging your feet.

Why so careful? Because any mark you make during these first hours could become permanent. It’s like walking on wet cement—what seems fine in the moment can leave impressions you’ll see forever.

Temperature makes a big difference here. In cooler weather, it might take 16 to 20 hours to feel dry. In warmer conditions, maybe only 6 to 8 hours. But regardless of how dry it feels, that 24-hour waiting period is your safety net.

Environmental Factors During Initial Set

Your garage environment during these first 24 hours can make or break your installation. Temperature needs to stay fairly steady—big swings can create problems that show up later.

Humidity is another factor to watch. Too much moisture in the air can create a cloudy haze on your floor called “blushing.” Once that happens, it’s really hard to fix. Keep humidity moderate and your epoxy flooring will cure clear and beautiful.

Keep the space clean during this time too. Dust or debris landing on wet epoxy gets trapped in the surface permanently. Close windows and doors as much as possible while still keeping air circulating for ventilation.

Light Traffic Period: Days 2-3 After Application

Congratulations! You’ve made it through the first 24 hours. Now you can start using your garage again, but with some limits.

What Activities Are Safe During This Phase

After 24 hours, you can walk normally on your epoxy flooring in regular shoes. You can also start bringing lighter items back into the garage—things like bikes, garden tools, and sports equipment are fine.

But take it easy with heavy stuff. Don’t drag anything across the floor, even if it has wheels. The epoxy is hard enough to walk on, but sliding or dragging can still leave marks. If you need to move something heavy, lift it or put soft pads underneath.

Sharp objects need extra caution during these days. Metal shelving legs, jack stands, or tool boxes with pointy corners can create dents if you’re not careful. Use protective pads or plywood under anything with concentrated weight.

Why Patience Matters in the Early Days

Think of your floor like a healing wound. It looks okay on the surface, but it’s still building strength underneath. Each day, it gets a little harder and a little stronger.

Many people get impatient during this phase. The floor looks done, feels solid, and you just want your garage back to normal. But a few extra days of caution now means decades of great performance later. It’s worth the wait.

Professionals like those at GLI Epoxy Flooring will tell you that most early failures happen because someone rushed this period. Give your floor the time it needs, and it’ll reward you with years of trouble-free service.

Full Mechanical Cure: The 72-Hour Milestone

Three days after application, your epoxy flooring reaches an important milestone. This is when it’s ready for heavier use.

When Can You Drive on Your Epoxy Floor

For most epoxy systems in normal conditions, 72 hours is when you can bring your car back into the garage. The coating has developed enough hardness and strength to handle vehicle weight.

But there are some caveats. If your garage was cooler than normal (below 65°F), wait an extra day or two. Temperature really affects how fast epoxy cures, and it’s better to be safe than sorry.

When you first park on your new floor, drive in gently. No sharp turns, no spinning tires, no aggressive braking. Even fully cured epoxy appreciates being treated with care, and yours is just reaching minimum readiness.

One more thing: if you’ve been driving and your tires are hot, let them cool for 15 minutes before parking on your new epoxy flooring. Hot tires on a newly cured floor can leave impressions that you’ll see forever.

Resuming Normal Garage Activities

At the 72-hour mark, you can start using your garage normally. Heavy tool chests, workbenches, and equipment can come back in. You can work on projects, park your car, and generally stop tiptoeing around.

That said, your floor is still gaining strength. It’s “good enough for normal use” but not completely finished with its curing process. Treat it reasonably well for the first week or two, and you’ll be rewarded with maximum durability.

Complete Chemical Cure: The Full 7-Day Process

While your floor is usable after three days, the chemical reaction continues for about a week total. This is when epoxy flooring reaches its full potential.

Why Epoxy Continues Hardening After a Week

Even after seven days, your epoxy is still technically curing—it’s just happening very slowly by this point. The molecules keep linking together, making the floor incrementally harder and stronger.

Professional installers often notice that floors feel noticeably harder at two weeks than at one week, and even harder at a month. The floor is fully usable after a week, but it keeps improving for a while longer.

Maximum Durability and Chemical Resistance Timeline

One of epoxy’s best features is its resistance to chemicals—oil, gas, antifreeze, and all the stuff that ends up on garage floors. But this chemical resistance takes time to fully develop.

After seven days, your epoxy flooring can handle typical garage chemicals just fine. Clean up spills reasonably quickly, and you won’t have any problems. By 30 days, the floor has reached its maximum chemical resistance and can handle just about anything.

During the first couple weeks, just be a little more careful with harsh chemicals. The floor will be fine with normal use, but avoiding prolonged exposure to strong solvents gives it the best chance to reach full maturity.

How Temperature Affects Epoxy Curing Time

Temperature plays a huge role in how quickly your epoxy flooring cures. Understanding this helps you plan better and set realistic expectations.

Cold Weather and Extended Cure Periods

When it’s cold, epoxy cures much more slowly. At 60°F, curing takes about 50% longer than at 70°F. At 50°F—the minimum temperature for most epoxies—it can take twice as long or more.

Let’s put numbers to this. An epoxy that’s ready for foot traffic in 24 hours at 70°F might need 36 hours at 60°F, and 48 hours at 50°F. The three-day vehicle traffic rule becomes four or five days in cooler conditions.

If you’re installing in cool weather, just plan on everything taking longer. Wait 48 hours before walking on the floor, five to seven days before driving on it, and two weeks before considering it fully cured. Patience in cold weather isn’t optional—it’s essential.

Hot Weather and Accelerated Curing

Heat speeds up the curing reaction. At 85°F, epoxy might be ready for foot traffic in 16 hours and vehicles in 48 hours. Sounds great, right?

Not so fast. While rapid curing might seem convenient, it can actually cause problems. The epoxy generates heat as it cures, and in already-hot conditions, this can lead to bubbling or cracking. Fast curing also means you have less time to work with the epoxy during application.

If you’ve applied epoxy flooring in hot weather, stick to the standard cure times anyway. Just because the surface hardens quickly doesn’t mean the entire coating depth has cured properly. Give it the full recommended time to ensure quality results.

Humidity’s Role in the Curing Process

Temperature gets all the attention, but humidity matters just as much for successful epoxy flooring curing.

Optimal Humidity Levels for Proper Curing

The sweet spot for humidity is between 40% and 70%. In this range, epoxy cures normally without moisture problems. The coating stays clear, adheres properly, and develops that nice glossy finish you want.

Really low humidity (below 40%) rarely causes issues. It’s much better to be too dry than too wet when it comes to epoxy curing.

Problems Caused by Excessive Moisture

When humidity climbs above 75-80%, you’re asking for trouble. High moisture can create several problems, the most common being “blushing”—a cloudy, whitish haze on the surface.

Blushing happens when moisture in the air reacts with the curing epoxy. Once it occurs, it’s really hard to remove. Sometimes you have to sand and recoat the entire floor.

High humidity can also slow down curing significantly. In extreme cases, epoxy flooring applied in very humid conditions might never fully harden, remaining soft or tacky in spots. These areas become dirt magnets and weak points in your floor.

Different Epoxy Types and Their Cure Schedules

Not all epoxy flooring products cure at the same speed. Understanding these differences helps you choose the right product and set proper expectations.

Fast-Cure vs. Standard Epoxy Systems

Standard epoxy systems follow the timelines we’ve been discussing: foot traffic after 24 hours, vehicles after 72 hours, full cure in seven days. These work well for most home garage applications.

Fast-cure epoxies use special formulas that speed things up. Some claim you can walk on them in 12 hours and drive on them in 24 to 36 hours. The trade-off? Much shorter working time during application, making them trickier to use.

For most homeowners, standard cure systems are the better choice. The extra day or two of waiting is worth the easier application process and more forgiving nature of the product.

Professional-Grade vs. DIY Formulations

Professional products used by companies like GLI Epoxy Flooring often have higher solids content than retail DIY products. This means more actual epoxy and less solvent.

These professional systems might feel harder after 24 hours than DIY products, even though initial cure times are similar. They often reach full hardness faster too. But they can also be trickier to work with without experience.

DIY-friendly products include additives that make them easier to apply. They might take slightly longer to cure completely, but the easier application usually makes them the better choice for first-time users.

Signs Your Epoxy Flooring Has Fully Cured

How can you tell when your epoxy flooring has actually finished curing? Here are some simple ways to check.

Visual Indicators of Complete Curing

Fully cured epoxy has consistent gloss across the entire floor. No dull spots, no hazy areas—just uniform shine everywhere. If you see inconsistencies, those areas might need more time.

The color should be stable throughout. Some epoxies darken slightly as they cure. Once the color stops changing, that’s a good sign the reaction is complete.

Check for tackiness by running your hand across different areas. The floor should feel completely dry and hard everywhere. Any spot that feels even slightly soft needs more time.

Testing Hardness and Durability

Here’s a simple test: press your thumbnail firmly into an out-of-the-way spot on the floor. Fully cured epoxy won’t show any impression at all. If you can leave even a faint mark, give it more time.

You can also try the coin test. Take a quarter and try to scratch the surface with its edge, using firm pressure. Fully cured epoxy flooring should resist scratching from a coin. If it leaves a mark, the epoxy is still soft.

These simple tests, combined with following the recommended time guidelines, tell you everything you need to know about whether your floor is ready.

What Happens If You Use Your Floor Too Soon

Let’s talk about what happens if you can’t wait and use your floor before it’s ready. The consequences range from minor blemishes to serious damage.

Damage from Premature Traffic

Walking on epoxy before 24 hours can leave permanent footprints. These aren’t temporary—they’re actual deformations in the curing coating that will be there forever.

Driving on epoxy flooring before 72 hours is even worse. Tire marks are the obvious problem, but you can also cause delamination where the epoxy separates from the concrete. Hot tires on partially cured epoxy can actually peel up sections of your new floor.

Dragging heavy objects across partially cured epoxy creates gouges and scratches that can’t be buffed out. The coating hasn’t developed full strength yet, so what would just scuff a fully cured floor can tear right through one that’s still curing.

Long-Term Consequences of Rushing the Process

Beyond immediate visible damage, using your floor too soon can cause problems that don’t show up for months. Premature loading can create tiny cracks that become pathways for moisture and chemicals to attack the bond between epoxy and concrete.

These problems grow over time. What starts as a barely noticeable soft spot gradually expands into bubbling or peeling. The floor might seem okay initially, but it never reaches the durability it should have.

Chemical resistance suffers too. A floor used too soon might absorb chemicals it should resist, leading to staining or deterioration that wouldn’t happen with properly cured epoxy.

Maximizing Cure Quality Through Proper Conditions

Getting your epoxy flooring to cure properly isn’t just about waiting—it’s about maintaining good conditions the whole time.

Maintaining Consistent Temperature

Steady temperature matters more than any single reading. Epoxy that cures at a constant 65°F will perform better than epoxy that swings between 70°F and 50°F, even though the average is fine.

If you’re using heaters or AC to control temperature, keep them running throughout the cure period. Yes, it costs a bit more on your electric bill, but it’s worth it for the quality results you’ll get.

Protecting Your Floor During the Cure Period

Keep people out with simple barriers or signs. It’s easy to forget and wander into the garage out of habit, so visual reminders help prevent accidents.

Keep the area clean. Don’t sweep nearby spaces or do anything that creates dust while your epoxy is curing. Dust that settles on wet epoxy becomes part of the surface forever.

Keep pets and kids away too. One curious pawprint or handprint becomes a permanent feature you’ll see every day. A little prevention during the cure period saves a lot of regret later.

Regional Variations in Curing Time

Where you live makes a difference in how long epoxy flooring takes to cure. Different climates present different challenges.

Northern regions with cold weather need longer cure times, especially in winter. Even heated garages can struggle to maintain consistent warmth for a full week. Spring and fall offer better conditions, but you still need to account for cooler temperatures extending the timeline.

Southern and desert climates deal with heat instead. Summer temperatures that hit 100°F+ can cause epoxy to cure too fast, creating potential problems. Early morning applications work better, and you might still need to extend cure times to ensure quality.

Humid coastal areas need to watch moisture levels carefully. High humidity can cause blushing and other problems, so dehumidifiers become important equipment during the cure period.

Companies like GLI Epoxy Flooring adjust their recommendations based on local climate realities. What works in Minnesota might not work in Arizona, and that’s okay—just plan accordingly for your specific area.

GLI Epoxy Flooring Serving the Purpleville and Beyond in Vaughan,ON

GLI Epoxy Flooring is dedicated to serving the diverse needs of the local community of Vaughan, ON. including individuals residing in neighborhood like Purpleville, With its convenient location near landmarks such as the Chatfield District Park, Mast Road Park and major intersections like Cityview Blvd & Summit Dr and Aldan Dr & Julian Dr (coordinates: 43.855268,-79.553995), we offer epoxy flooring services.

Get Epoxy Flooring Services at Purpleville Now.

Navigate from Purpleville to GLI Epoxy Flooring

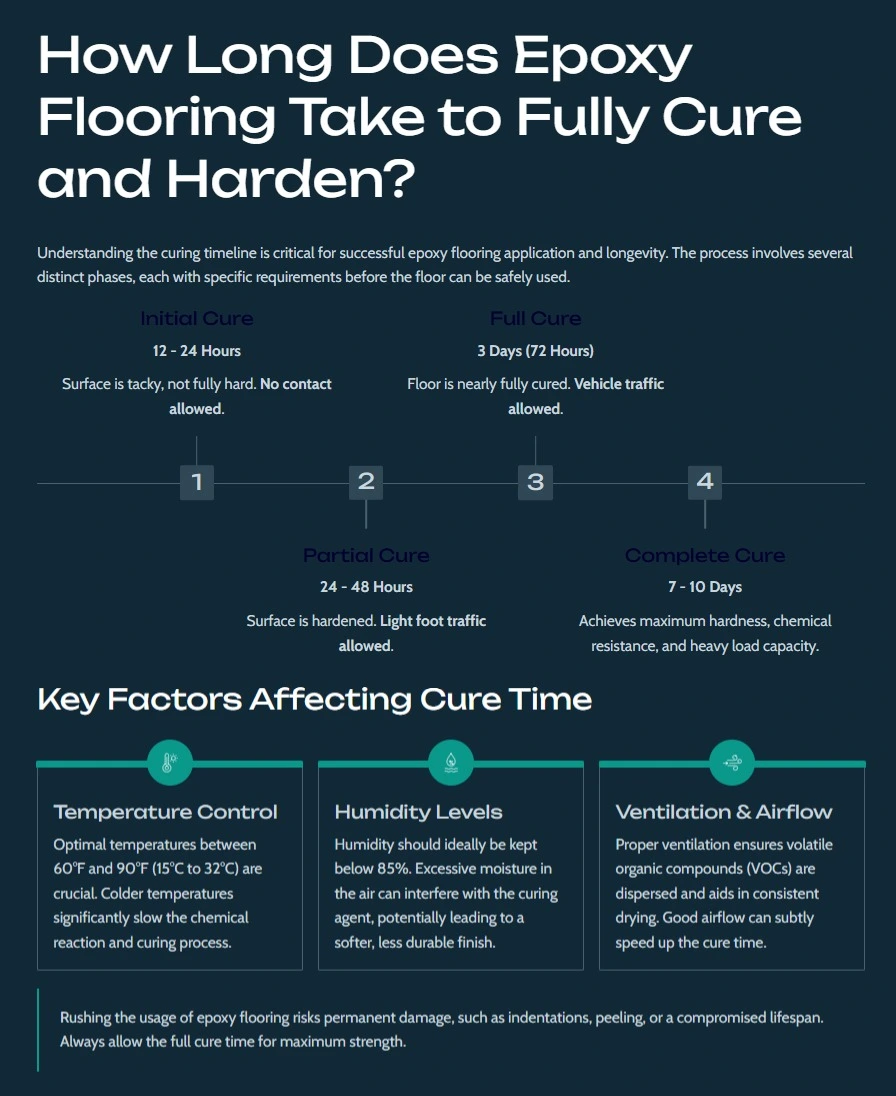

How Long Does Epoxy Flooring Take to Fully Cure and Harden?

Epoxy Flooring Curing Timeline & Key Stats

Phase Timeframe Surface State Usage Allowed Initial Cure 12 – 24 hours Tacky, not fully hard No contact Partial Cure 24 – 48 hours Hardened surface Foot traffic allowed Full Cure 3 days (72 hours) Nearly fully cured Vehicle traffic allowed Complete Cure 7 – 10 days Maximum hardness Heavy loads & chemical resistance

Environmental Factors Affecting Cure Time:

- Optimal temperature: 60°F to 90°F (15°C to 32°C)

- Humidity below 85% recommended

- Proper ventilation and airflow speed curing

Additional Notes:

- Some epoxies continue curing up to 2 weeks for full strength

- Accelerators and heat application can shorten cure time

- Rushing use risks permanent damage like indentations or peeling

Sources: ParadigmConcreteFL, BestBarTopEpoxy, EpoxyColorado, NationalConcretePolishing (2025)

So how long does epoxy flooring take to fully cure and harden? The simple answer: seven days for complete cure, though you can walk on it after 24 hours and drive on it after 72 hours.

But as we’ve covered, there’s more to the story than just these numbers. Temperature, humidity, and proper care during the cure period all play important roles in getting great results. Each phase of curing has its own rules about what you can and can’t do.

The key takeaway? Patience pays off. Those few extra days of waiting and careful use translate into years—even decades—of reliable performance. A floor that’s given proper time to cure will outlast one that was rushed, often by a significant margin.

Whether you’re doing it yourself or working with professionals like GLI Epoxy Flooring, understanding the curing process helps you plan better and avoid mistakes. The chemistry is predictable and reliable when you give it what it needs: proper conditions and adequate time.

Remember: what feels dry to the touch isn’t necessarily ready for use. Respect the timeline, maintain good conditions, and give your epoxy flooring the time it needs to reach full strength. Your patience during these crucial days will be rewarded with a beautiful, durable floor that serves you well for many years to come.

FAQs

Can I speed up epoxy curing by cranking up the heat in my garage?

While warmer temps do speed up curing, overheating your garage isn’t a great idea. Temperatures above 90°F can cause the epoxy to cure too fast, leading to bubbles, uneven curing, and other problems. It’s better to keep things steady around 65-75°F than to try forcing faster results with excessive heat. Slow and steady really does win this race.

What if my epoxy still feels soft after a week?

If your epoxy flooring hasn’t hardened properly after the recommended time, first check whether temperature was consistently warm enough. Cool garages are the usual culprit—if it was below 60°F for long periods, the floor just needs more time. Give it another few days and check again. If it’s still soft despite good conditions, there might have been a mixing error or moisture issue. In that case, you might need to start over.

Does a thicker coat of epoxy take longer to cure?

Yes, definitely. Thicker coats take longer to cure all the way through and generate more heat during the process. A standard garage floor coating follows typical cure times, but if you applied an extra-thick layer, add a day or two to all the timelines. Most epoxy systems are designed to be applied in relatively thin coats for this exact reason—it gives more predictable, reliable curing.

Can I add a second coat before the first one fully cures?

It depends on timing. Most epoxies have a “recoat window”—usually 4 to 24 hours after application—when you can add another coat without sanding in between. The first coat is hard enough to work on but hasn’t completely cured, so the coats bond really well. Once that window closes and the first coat fully cures, you’ll need to lightly sand before adding more epoxy. Just remember that each coat needs its own cure time before you can drive on the floor.

Will cold concrete slow down curing even if the air feels warm?

Absolutely. Concrete temperature matters more than air temperature because your epoxy sits right on that concrete slab. In spring, your concrete might be 10-15 degrees cooler than the air because it takes time to warm up from winter. Always check the actual concrete temperature with an infrared thermometer—don’t just assume it matches the air. If your concrete is below 50°F, the epoxy flooring will cure very slowly no matter how warm the air feels. You can warm it up by heating your garage for a few days before you start.