Have you ever wondered why some epoxy floors turn out flawless while others end up bubbling, peeling, or never quite hardening properly? The secret often lies not in the product quality or application technique alone, but in something far simpler: timing. Choosing the right season to install epoxy flooring in your garage can mean the difference between a floor that lasts decades and one that fails within months.

Think of epoxy installation like planting a garden—you wouldn’t sow seeds in frozen ground or during a heatwave, right? The same principle applies here. Epoxy is a chemical marvel that transforms your concrete garage floor into a durable, attractive surface, but it’s also surprisingly sensitive to environmental conditions. Temperature, humidity, and even the concrete’s own temperature play crucial roles in determining whether your installation succeeds or fails.

Throughout this guide, we’ll walk through every season, examining the pros and cons of each, and help you pinpoint the perfect installation window for your specific climate. Whether you’re in the frosty north or the sunny south, understanding these timing principles will save you headaches, money, and ensure your garage floor looks professional for years to come.

Understanding How Weather Affects Epoxy Flooring Installation

Before we dive into specific seasons, let’s understand why weather matters so much for epoxy flooring north york. Epoxy isn’t just paint—it’s a two-part chemical system that undergoes a curing process through a chemical reaction. When you mix the resin and hardener, they begin transforming from liquid to solid through a process called polymerization. This transformation is highly temperature-dependent.

Temperature Requirements for Epoxy Application

Most epoxy flooring systems require ambient temperatures between 50°F and 90°F (10°C to 32°C) during both application and curing. Why this range? Below 50°F, the chemical reaction slows dramatically, sometimes grinding to a near halt. The epoxy might take weeks to cure instead of days, leaving it vulnerable to damage and potentially never achieving full hardness.

On the flip side, temperatures above 90°F accelerate the reaction too quickly. This rapid curing doesn’t give you adequate working time to spread the epoxy evenly, and it can cause the material to cure unevenly, leading to weak spots. Fast curing also generates more heat during the exothermic reaction, which can create bubbles in the finish.

But here’s where it gets tricky—the concrete temperature matters even more than air temperature. Your garage floor acts like a thermal battery, absorbing and releasing heat slowly. A concrete slab can be significantly colder than the air in spring or warmer than the air in fall. This temperature lag affects adhesion and curing in ways many DIYers don’t anticipate.

Humidity Levels and Their Impact on Curing

Humidity is the silent killer of epoxy installations. When moisture levels climb above 85%, you’re asking for trouble. Excess humidity can cause several problems: moisture can become trapped under the epoxy coating, creating cloudy patches or “blushing” in the finish. High humidity also interferes with the curing process, potentially leaving the surface tacky longer than expected.

Conversely, extremely low humidity (below 30%) isn’t ideal either, particularly in very hot conditions, as it can cause the epoxy to skin over too quickly before it’s properly leveled. The sweet spot? Relative humidity between 40% and 70% gives you the best working conditions and ensures proper curing.

Spring Installation: The Sweet Spot for Epoxy Flooring

For most regions, spring emerges as the champion season for installing epoxy flooring in your garage. There’s something almost poetic about starting fresh projects as nature renews itself, and the weather conditions typically align beautifully with epoxy requirements.

Why Spring Offers Ideal Temperature Ranges

Spring’s moderate temperatures hit that Goldilocks zone—not too hot, not too cold. In most of North America, late April through early June provides consistent temperatures between 55°F and 75°F. These conditions allow the epoxy to cure at a steady, predictable rate, giving you ample working time (typically 30-45 minutes) to spread and smooth the coating.

The gradual warming trend in spring also means your concrete slab is warming up rather than cooling down. This ascending temperature pattern is preferable because it reduces the risk of condensation forming under your freshly applied epoxy. When concrete warms, any moisture tends to evaporate away rather than condensing on the surface.

According to installation data tracked by GLI Epoxy Flooring, spring installations show a 15% lower callback rate for adhesion issues compared to installations performed in other seasons. This isn’t coincidence—it’s physics working in your favor.

Managing Moisture During Spring Months

Spring does come with one significant challenge: rain. Springtime is notoriously wet in many regions, which creates two concerns for epoxy projects. First, you need several consecutive dry days for installation. The concrete must be completely dry before you apply epoxy—even slight dampness will prevent proper adhesion.

Second, humidity levels can spike after rain events. You’ll need to monitor both the weather forecast and indoor garage humidity levels. A simple humidity meter (available for under $20) becomes your best friend during spring installations. Plan your project for a weather window of at least three dry days, with moderate humidity throughout.

One practical tip: if you’ve had recent rainfall, wait at least 48-72 hours after the last rain before beginning your installation, even if the forecast looks perfect. This waiting period allows ground moisture to dissipate and your concrete slab to reach equilibrium with the drier conditions.

Summer Considerations for Garage Epoxy Projects

Summer might seem like the obvious choice—school’s out, you have vacation time, and the weather is consistently warm. However, summer installations require more careful planning and present unique challenges that can trip up even experienced installers.

Dealing with High Temperatures and Fast Curing

When temperatures climb into the 80s and 90s, epoxy behavior changes dramatically. The working time—also called “pot life”—shrinks considerably. An epoxy that gives you 45 minutes to work at 70°F might give you only 15-20 minutes at 90°F. This accelerated timeline means you need to work faster and more decisively, with less room for error or adjustment.

The rapid curing also affects how you mix the components. In hot weather, you should mix smaller batches to avoid having the epoxy kick off (start hardening) in your bucket before you can spread it. Some professionals even place their unmixed epoxy components in air-conditioned spaces or coolers before use to buy themselves extra working time.

Heat also exacerbates the exothermic reaction. As epoxy cures, it generates heat—this is normal. But in already hot conditions, this additional heat can cause the coating to cure unevenly or develop bubbles as trapped air and moisture try to escape through the rapidly hardening surface.

If you’re determined to install during summer, early morning becomes your friend. Starting your project at 6 or 7 AM, when temperatures are coolest, gives you several hours of workable conditions before the day heats up. Many professionals refuse to work on epoxy installations when afternoon temperatures will exceed 85°F.

Ventilation Requirements in Hot Weather

Summer installations demand excellent ventilation, but here’s the catch-22: you need air movement without letting in hot air that will speed up curing even more. Opening your garage door helps, but you might be inviting 95°F air inside. Using fans strategically—positioned to move air without directly blowing on wet epoxy—helps moderate temperature while providing the airflow needed for fume dispersal.

The fumes from epoxy are more pronounced in heat, making proper respiratory protection essential. Don’t skimp on ventilation because you’re trying to maintain cooler temperatures. Your health comes first, and those fumes need somewhere to go.

Fall as a Prime Window for Epoxy Floor Installation

If spring is the golden season for epoxy flooring installation, fall runs a very close second—and in some regions, it might actually be the better choice. Fall offers a unique combination of advantages that make it a favorite among professional installers.

Stable Temperature Benefits in Autumn

September through early November typically provides the most stable temperature patterns of the year. Unlike spring, when temperatures can swing wildly from day to day, fall tends to offer more consistent conditions. This stability makes planning easier and reduces the risk of unexpected weather derailing your project.

The cooling trend also means your concrete slab is releasing stored summer heat gradually. This descending temperature pattern is generally favorable, though you need to watch for the point where nighttime temperatures dip too low. In most temperate climates, mid-September through mid-October provides the sweet spot where daytime highs remain in the 60s and 70s, while nighttime lows stay above 45°F.

Fall also brings lower humidity in many regions. After summer’s oppressive moisture levels, autumn air tends to be drier and more comfortable. This reduced humidity translates directly to better epoxy adhesion and clearer, more attractive finishes without the blushing or clouding that high humidity can cause.

GLI Epoxy Flooring reports that fall installations often cure to a harder finish than summer installations, likely due to the slower, more controlled curing process that moderate temperatures allow.

Preparing Your Garage Before Winter Arrives

There’s a psychological advantage to fall installations too—you’re getting your garage ready for winter. A freshly coated epoxy floor gives you a clean, sealed surface that’s easier to clean when snow, ice, and road salt start making their way into your garage. The epoxy creates a protective barrier that prevents road chemicals from damaging your concrete during the harsh winter months.

Timing your fall installation also means you’re working with concrete that’s had all summer to fully cure if it’s new construction. New concrete should cure for at least 30 days (preferably 60) before epoxy application, so if you poured a garage floor in summer, fall becomes the natural installation window.

Winter Challenges for Epoxy Flooring Projects

Let’s be direct: winter is the most challenging season for installing epoxy flooring, and in many climates, it’s simply not advisable. However, understanding winter’s limitations helps you appreciate why seasonal timing matters so much.

Cold Temperature Limitations

When temperatures drop below 50°F, epoxy chemistry fundamentally changes. The curing reaction slows exponentially—some products may not cure at all below 40°F. Even if the air temperature in your garage hovers around 55°F, remember that your concrete slab is likely significantly colder, possibly below the minimum application temperature.

Cold concrete also contracts slightly, and any moisture in or near the surface can freeze and expand. This freeze-thaw cycle is epoxy’s enemy. Ice crystals forming under a fresh epoxy coat will push it away from the concrete, destroying adhesion. Even if temperatures are above freezing during application, overnight freezing can ruin a fresh installation.

Some manufacturers offer “winter-grade” or cold-cure epoxy formulations designed for lower temperatures, typically working down to 35-40°F. These specialized products use different hardeners that remain reactive in cold conditions. However, they’re more expensive, have shorter shelf lives, and still require the concrete temperature to be within acceptable ranges—not just the air temperature.

Extended Curing Times in Winter Conditions

Even if you manage to apply epoxy in winter, the extended curing time creates problems. An epoxy that fully cures in 72 hours at 70°F might take a week or more at 50°F. During this extended cure period, your floor remains vulnerable to damage, dust contamination, and tracking.

The longer cure time also means extended exposure to potential temperature fluctuations. If temperatures drop overnight during the cure period, you risk incomplete curing sections that will remain soft or tacky indefinitely. These weak spots become failure points where the coating will eventually peel or wear through prematurely.

Regional Climate Variations and Timing Strategies

Not all regions experience seasons the same way, so your optimal installation window depends heavily on where you live. Let’s break down timing strategies by climate zone.

Northern Climate Considerations

If you live in the northern United States or Canada, your installation window is compressed into a shorter period. Late May through June offers spring conditions, while September through early October provides fall opportunities. July and August, despite being summer, are often acceptable with early morning installations.

The key in northern climates is avoiding the shoulder seasons—late October through April typically offers too many cold days and freezing nights. If you miss your window, it’s better to wait until spring than risk a winter installation failure. Heating your garage is possible but expensive and tricky to maintain the consistent temperatures needed throughout the multi-day curing process.

Southern and Warm Climate Scheduling

In southern states, you have more flexibility but different challenges. The mild winters of the Deep South mean you can install epoxy flooring almost year-round, though you’ll want to avoid the hottest summer months. In Texas, Arizona, and Florida, November through April typically provides ideal conditions.

The Gulf Coast and southeastern states need to watch humidity more than temperature. Summer months can bring 90%+ humidity regularly, making even moderate temperatures problematic for epoxy. Planning installations around weather patterns—avoiding the monsoon season in the Southwest or the summer storm season in Florida—becomes more important than picking a specific month.

California and other Mediterranean climates have the longest installation windows, with late February through early June and September through November all providing excellent conditions in most areas.

How to Monitor Weather Conditions Before Installation

Success with epoxy flooring comes down to preparation, and nothing matters more than monitoring conditions before and during your project.

Using Weather Forecasts for Planning

Start watching extended forecasts two weeks before your planned installation date. You’re looking for a three-to-four-day window of stable temperatures within the 55-75°F range, with no rain predicted and humidity levels below 80%. Be flexible—if the forecast changes, postpone your project rather than gambling on marginal conditions.

Modern weather apps provide hourly temperature and humidity predictions. Use these to plan your application timing. If you see that Day 2 of your cure period might dip below 50°F overnight, reschedule. The few days of delay are infinitely better than a failed installation.

Pay particular attention to dew point temperatures. When the concrete temperature drops to the dew point, condensation forms on the surface—absolute death for epoxy adhesion. Your concrete temperature should be at least 5°F above the dew point throughout the application and initial curing period.

Indoor Temperature Control Options

If you have climate control in your garage, you’ve got more flexibility. Maintaining temperatures between 60-75°F with a heater or air conditioner expands your installation window significantly. However, this approach requires commitment—you’ll need to maintain those conditions for the entire cure period, typically 72-96 hours minimum.

Space heaters can work for heating, but avoid kerosene or propane models that produce moisture as a combustion byproduct. Electric heaters are cleaner, though more expensive to run. Make sure your garage is reasonably insulated and can maintain temperature overnight. A garage that loses 10-15 degrees overnight despite heating is still too variable for reliable epoxy curing.

Dehumidifiers become valuable tools in humid climates or damp garages. Running a dehumidifier for 24-48 hours before installation helps ensure your concrete is thoroughly dry and maintains optimal humidity during curing.

The Role of Concrete Temperature in Epoxy Success

Here’s something many DIYers miss: the concrete temperature matters more than the air temperature around it. You can have a beautiful 70°F day, but if your concrete slab is only 45°F from weeks of cold weather, your epoxy flooring installation will fail.

Concrete is a thermal mass—it absorbs and releases heat slowly. In spring, your slab might be 10-15 degrees cooler than the air temperature. In fall, it might be 10-15 degrees warmer, holding onto summer heat. This thermal lag is why spring installations can be tricky early in the season, and why fall installations remain possible later than you might expect.

Testing concrete temperature is simple: use an infrared thermometer (about $25 at hardware stores) to check your slab temperature in several locations. Do this at the time of day you plan to apply the epoxy. If readings are outside the 50-90°F range, you need to wait or adjust your timing.

GLI Epoxy Flooring recommends monitoring concrete temperature for three days before installation to understand how your slab responds to daily temperature cycles. This data helps you predict whether overnight cooling will drop your slab below acceptable temperatures during the critical curing period.

Seasonal Humidity Patterns and Epoxy Adhesion

Humidity deserves its own discussion because it’s the factor most often overlooked by DIY installers. Every region has seasonal humidity patterns, and understanding these patterns helps you choose the right installation window.

Spring humidity varies by region—wet in the East and Midwest, drier in the West. Summer brings high humidity almost everywhere, particularly in mornings and evenings. Fall typically offers the lowest humidity of the year, especially in northern and western regions. Winter can be deceptively dry indoors but may bring high humidity in moderate climates with frequent rain.

The relationship between temperature and humidity creates additional complexity. Warm air holds more moisture, so that 70% humidity reading at 85°F contains much more actual moisture than 70% humidity at 55°F. This is why summer installations are problematic even when humidity readings seem acceptable—the absolute moisture content is much higher.

For the best epoxy flooring results, aim for relative humidity between 40-70% during application and initial curing. If humidity climbs above 80%, postpone your project. The risk of moisture-related defects isn’t worth the gamble.

Planning Your Installation Timeline

Successful epoxy installation isn’t just about picking the right season—it’s about planning the entire timeline from concrete preparation through final curing.

Allowing Proper Concrete Curing Time

If you’re working with new concrete, patience is essential. Fresh concrete continues curing for months, but it needs at least 30 days before epoxy application—60 days is better. During this period, moisture migrates out of the slab, and the concrete reaches its design strength.

Applying epoxy too early traps moisture in the concrete, creating bubbles, blisters, and adhesion failures down the road. Even if the surface feels dry, deep moisture can still be present. Simple moisture tests (like taping plastic to the floor and checking for condensation after 24 hours) can reveal hidden moisture issues.

Scheduling Around Garage Usage Needs

Your garage will be out of commission for several days during epoxy installation. Beyond the application day, you need at least 24-48 hours before walking on the surface, and 72-96 hours before driving on it. Plan this downtime around your schedule.

Many homeowners prefer fall installations for this reason—kids are back in school, summer travels are over, and you’re settling into routines where having the garage unavailable for a week won’t disrupt major plans. Spring break might seem like a good DIY window, but if your installation coincides with vacation plans requiring your vehicle, you’ve created unnecessary stress.

GLI Epoxy Flooring Serving the York University Heights and Beyond in North York, ON

GLI Epoxy Flooring is dedicated to serving the diverse needs of the local community of North York, including individuals residing in neighborhood like “York University Heights” With its convenient location near landmarks such as the Black Creek Parkland, York University

major intersections like Keele St & Finch Ave W and Sentinel Rd & Finch Ave W (coordinates: 43.765452, -79.491875), We offer Epoxy Flooring services.

Get Epoxy Flooring Services at University Heights Now.

Navigate from York University Heights to GLI Epoxy Flooring

When Is the Best Time of Year to Install Epoxy Flooring in Your Garage?

Optimal Installation Conditions for Epoxy Garage Floors

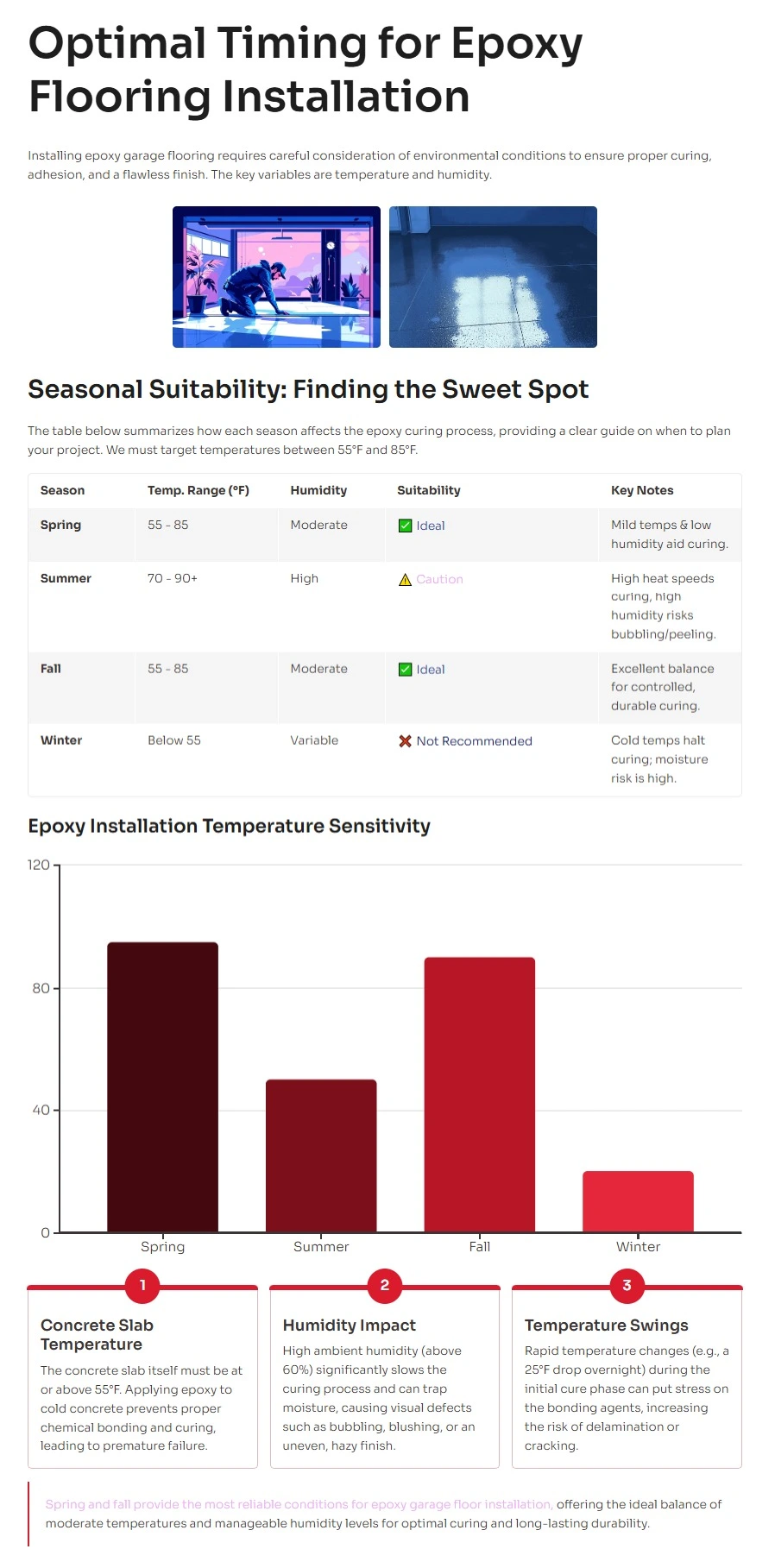

Season Typical Temperature Range (°F) Humidity Level Suitability for Epoxy Installation Key Notes Spring 55 – 85 Moderate ✅ Ideal Mild temps & low humidity aid curing Summer 70 – 90+ High ⚠️ Caution High heat speeds curing, may cause uneven finish; humidity can cause bubbles Fall 55 – 85 Moderate ✅ Ideal Similar to spring, best balance for curing Winter Below 55 Variable ❌ Not recommended Cold temps slow or stop curing; moisture risk

Additional Factors:

- Concrete slab temperature must be above 55°F for epoxy to cure properly.

- High humidity slows curing and can cause defects like bubbling or peeling.

- Polyaspartic coatings offer more temperature flexibility but epoxy requires moderate temps.

- Rapid temperature swings (e.g., Florida’s 85°F day to 60°F night) increase risk of cracking or peeling in standard epoxy.

Summary: Spring and fall provide the most reliable conditions for epoxy garage floor installation, balancing temperature and humidity for optimal curing and durability

Sources: Lifetime Green Coatings (2024), ICM Coating Masters (2025), Solid Garage Floor Coatings, Top Gun Garage (Florida climate study)

So, when is the best time of year to install epoxy flooring in your garage? For most homeowners in temperate climates, late spring (May through early June) and early fall (September through early October) offer optimal conditions. These periods provide moderate temperatures, stable weather patterns, and manageable humidity levels that allow epoxy to cure properly and achieve its full durability potential.

However, the “best” time ultimately depends on your specific location and climate. Southern residents might find winter ideal, while northern homeowners have a narrower window. The key takeaway isn’t about memorizing specific months—it’s about understanding the temperature and humidity requirements that make epoxy installation successful, then monitoring your local conditions to identify the right window.

Remember, experts like those at GLI Epoxy Flooring emphasize that patience pays off. Waiting for perfect conditions might mean delaying your project by weeks or even months, but that patience ensures your garage floor looks great and lasts for decades. A rushed installation in marginal conditions is worse than no installation at all.

Think of it this way: you’re not just coating your garage floor—you’re making an investment in your home. Choosing the right installation season is like choosing quality materials and proper preparation: it’s the foundation for success. Whether you’re a DIY enthusiast or hiring professionals, respecting the seasonal requirements of epoxy flooring is the difference between a floor you’ll be proud of and one you’ll regret.

FAQs

What happens if it rains shortly after installing epoxy flooring in my garage?

If rain occurs within the first 24 hours after applying epoxy, especially if your garage door was open or water enters the space, it can cause significant damage to the uncured coating. Water contamination can create cloudy spots, affect adhesion, and prevent proper curing. The epoxy needs to cure undisturbed in controlled conditions. If rain is forecasted within 48 hours of your planned installation, it’s best to postpone the project until you have a guaranteed dry period covering both application and initial curing time.

Can I use space heaters to install epoxy flooring during winter months?

While space heaters can help maintain adequate temperatures for epoxy installation in cooler months, this approach requires careful execution. You need to maintain consistent temperatures between 60-75°F not just during application but throughout the entire 72-96 hour curing period. The garage should be reasonably insulated to prevent excessive heat loss. Avoid propane or kerosene heaters that produce moisture as a byproduct—use electric heaters instead. Additionally, the concrete slab temperature must be within the acceptable range, which might require several days of heating before you even begin application.

How do I know if my concrete is too cold for epoxy application?

The most reliable method is using an infrared thermometer to measure the concrete surface temperature directly. Take readings in multiple locations across your garage floor at the time of day you plan to apply the epoxy. If any readings fall below 50°F, the concrete is too cold for standard epoxy products. Remember that concrete temperature often lags behind air temperature—your garage might feel comfortable at 65°F, but the slab could still be 45°F from previous cold weather. Check temperatures for several days before installation to understand how your slab responds to temperature changes.

Is morning or afternoon better for applying epoxy flooring?

The optimal time depends on the season. During summer, early morning application (starting around 6-7 AM) is preferable because temperatures are coolest, giving you maximum working time before heat accelerates curing. In spring and fall, late morning to early afternoon often works best when temperatures have risen to comfortable levels but won’t drop too quickly as evening approaches. During any season, avoid starting so late that temperatures might drop below 50°F during the critical first 12 hours of curing. Always check both current temperature and forecasted overnight lows before beginning.

Does humidity affect epoxy flooring differently in different seasons?

Yes, seasonal humidity behaves differently and affects epoxy accordingly. Spring humidity is often accompanied by cooler temperatures, which means lower absolute moisture even if relative humidity readings seem high. Summer humidity combined with heat creates the most moisture-laden air, increasing the risk of blushing, clouding, and adhesion problems. Fall typically offers the best humidity conditions with drier air in most regions. Winter humidity can be deceptive—indoor heated spaces may have very low humidity, but outdoor or unheated garage humidity might be high, especially during freeze-thaw cycles. Always measure actual humidity in your garage space, not just outdoor conditions, and aim for 40-70% relative humidity during installation.