Epoxy Floor Coating is admired for its glass-like shine and its long-lasting, protective surface, but even the best installations can develop a yellowish hue over time. This subtle shift in color doesn’t happen suddenly — it’s the result of ongoing exposure to light, heat, and air, which slowly alter the chemical bonds within the coating. The once-crystal-clear surface begins reflecting warmer tones because of natural aging and molecular changes. For homeowners and facility managers, this can be confusing, as the floor still feels strong and smooth but no longer looks as bright as the day it was installed.

Professionals at GLI Epoxy Flooring often explain that this yellowing process is entirely normal and rooted in material science. Epoxy resins are made of complex polymers that respond to their surroundings. Sunlight, temperature shifts, and cleaning chemicals all influence how these polymers behave. Knowing why epoxy changes color allows you to maintain the floor’s clarity and prevent premature discoloration. With proper installation and care, epoxy floor coating in environments like Toronto can stay visually consistent for many years before any noticeable yellowing occurs.

The Science Behind Epoxy Floor Coating

Unlike traditional paints that dry through evaporation, Epoxy Floor Coating Toronto cures through a chemical reaction. When the resin and hardener are combined, they form a dense, cross-linked network that provides hardness, impact resistance, and a smooth finish. This network, however, is sensitive to ultraviolet (UV) radiation. Over time, UV light can disrupt the polymer structure, causing molecular bonds to weaken and reflect yellow wavelengths instead of clear light. This is why epoxy floors exposed to sunlight or strong indoor lighting gradually change in tone.

In controlled laboratory conditions, epoxy floor coating remains stable for extended periods. But in real-world use, UV rays and heat become unavoidable stressors. The surface chemistry reacts subtly to these forces, initiating what chemists call “photo-oxidation.” Even small amounts of UV exposure can begin this chain reaction, which continues slowly over months and years. The result is an optical transformation that affects appearance more than performance — though without proper protection, extended degradation may lead to surface dullness and reduced gloss.

Natural Aging and Chemical Oxidation

Epoxy coatings undergo oxidation even in the absence of sunlight. When oxygen in the air interacts with the cured resin, it triggers small chemical reactions that create chromophores — microscopic color-forming particles that absorb blue light and reflect yellow. It’s the same process that causes old plastics or clear adhesives to develop an amber tint. This natural oxidation doesn’t weaken the coating but changes how it reflects light, making the surface appear warmer or darker.

Temperature accelerates oxidation dramatically. In garages or industrial spaces where floors are exposed to higher ambient heat or mechanical friction, the reaction rate increases. Over time, these repeated heat cycles gradually transform the surface color. At GLI Epoxy Flooring, technicians often see this in older facilities where epoxy near machinery or heat vents yellows faster than areas in consistent shade. While oxidation can’t be fully avoided, it can be slowed significantly with UV-resistant formulations and protective sealants.

Key Factors That Contribute to Yellowing

Several environmental and chemical factors combine to influence how quickly epoxy floor coating changes color. Light exposure, heat, moisture, and even the products used for cleaning can play a role. Understanding each of these variables helps identify what’s within your control and what simply comes with time.

The key takeaway is that epoxy’s molecular structure is dynamic — meaning it continues to interact with its environment long after installation. That interaction defines how fast or slow yellowing progresses. Let’s break down the main culprits responsible for the color shift.

UV Radiation and Its Effect on Polymers

Ultraviolet light is by far the strongest factor in epoxy yellowing. When sunlight hits the coating, UV photons penetrate the polymer surface and break carbon–carbon bonds, causing structural changes. These new molecular arrangements absorb light differently, producing a yellow appearance. The effect is cumulative, meaning the longer the exposure, the deeper the discoloration.

Even indoor epoxy floor coating in Toronto can be affected if located near large windows, skylights, or glass doors. Ordinary glass only filters a portion of UV radiation. Over time, daily exposure adds up, especially in bright, sun-facing areas. Using UV-stable epoxy formulations and tinted topcoats significantly minimizes this risk, keeping the floor coating clear and consistent.

The Role of Heat and Temperature Variations

Heat not only speeds up oxidation but also softens the epoxy’s top layer temporarily, allowing oxygen and light to penetrate deeper into the surface. Areas near radiators, heating ducts, or industrial machines often show earlier signs of yellowing compared to cooler zones. Sudden temperature swings can also create internal stresses that alter how the resin reflects light.

In residential settings, garages with limited ventilation or direct sunlight exposure tend to develop uneven discoloration — darker near doors and lighter inside. This variation is purely a result of localized heat differences. Consistent indoor temperatures and reflective window films help reduce these effects by stabilizing the epoxy’s reaction rate.

Chemical Reactions Within the Coating Layer

Not all yellowing comes from external sources. Sometimes, the cause lies within the epoxy formulation itself. Certain chemical additives, leftover solvents, or incompatible mixtures of resin and hardener can trigger minor reactions long after installation. Over months, these internal reactions can slightly alter the coating’s clarity, particularly in areas where the mix ratio was imprecise.

Household cleaning products are another factor. Many commercial cleaners contain ammonia or strong acids, both of which can react with the surface, breaking down the outer layer’s resistance. Regular use of these substances weakens the polymer structure, allowing discoloration to appear more quickly. For this reason, experts recommend using pH-neutral cleaning agents specifically designed for coated floors.

Impact of Moisture and Environmental Pollutants

Moisture intrusion during or after installation can create microscopic surface imperfections where oxidation occurs faster. In humid climates, condensation may form under the top layer, accelerating yellowing by promoting additional chemical reactions. Even trace amounts of water vapor can lead to hazing or cloudiness that distorts the color tone.

Pollutants in the air, such as cigarette smoke, industrial emissions, or cooking residues, can also leave a film on the epoxy surface. This layer gradually darkens under UV exposure, creating an illusion of deep yellowing even when the resin itself is stable. Regular cleaning and maintaining good ventilation are simple but powerful ways to prevent this buildup.

How Epoxy Formulas Influence Color Stability

The formulation of the epoxy floor coating plays a major role in how it reacts to light and oxygen. Cheaper or older systems often lack additives that prevent yellowing, while modern versions include chemical stabilizers and modified polymers specifically engineered for clarity retention. Choosing the right formulation is essential for long-term performance.

Manufacturers have developed multiple categories of epoxy resins, each with different resistance levels to light, heat, and moisture. Understanding these differences helps in selecting coatings that best suit your environment — whether it’s a residential garage or a high-traffic industrial warehouse.

Difference Between Standard and UV-Resistant Epoxy

Standard epoxy systems typically use bisphenol-A resins, which are durable but sensitive to sunlight. These resins oxidize easily, especially when mixed with aromatic hardeners. UV-resistant epoxies, on the other hand, use modified resins and stabilizers that absorb or scatter UV light before it can harm the polymer structure. The result is a coating that retains its clarity longer and yellows much more slowly.

For facilities in Toronto or other regions with strong seasonal sunlight, UV-resistant epoxy systems are highly beneficial. Even in indoor spaces, reflected sunlight from windows and skylights can cause gradual fading. Opting for UV-stable coatings ensures better optical performance and long-term aesthetic stability.

How Additives and Hardeners Affect Longevity

The type of hardener used in epoxy plays a major role in its color stability. Aromatic amine hardeners cure quickly but are prone to oxidation and discoloration. Cycloaliphatic or aliphatic amines form tighter molecular bonds that resist oxidation and UV damage. This is why professional installers prefer advanced aliphatic systems for clear finishes or decorative coatings.

In addition to hardeners, additives such as HALS (Hindered Amine Light Stabilizers) and UV absorbers are increasingly common. These compounds work synergistically — UV absorbers capture high-energy light, while HALS neutralize the free radicals formed by it. This two-layer protection dramatically improves the clarity and lifespan of epoxy coatings.

Identifying Early Signs of Epoxy Yellowing

Yellowing rarely happens suddenly. The process begins subtly and gradually becomes noticeable over time. Recognizing the early signs allows homeowners and maintenance teams to take preventive action before discoloration becomes irreversible.

Visual cues, texture changes, and gloss loss all indicate that the epoxy surface is beginning to degrade. Monitoring these symptoms helps maintain the coating’s original aesthetic and performance.

Subtle Changes in Gloss and Clarity

The first indicator of yellowing is often a loss of high-gloss reflectivity. The surface begins to look dull or slightly hazy under natural light. This happens because the polymer’s microstructure changes how it refracts light. While the coating remains physically intact, the altered surface scattering causes it to appear cloudy.

In brightly lit commercial areas, this dulling effect is easier to notice. Floors that once looked mirror-smooth may now seem matte or uneven. Regular inspection under consistent lighting conditions can help identify such changes early.

Visible Color Shifts and Surface Dullness

After prolonged exposure, the color change becomes visible even to the untrained eye. The floor may appear golden, amber, or even brownish depending on how long the oxidation has occurred. These tonal shifts are more apparent near windows, doorways, or high-traffic areas where cleaning and wear are frequent.

Once discoloration reaches this stage, it usually cannot be reversed without re-coating. However, prompt action — such as applying a UV-resistant topcoat — can stop the process from progressing further. Recognizing these visual patterns allows for timely maintenance interventions.

The Chemistry Behind UV-Induced Degradation

UV-induced degradation is a chemical process called photooxidation. When ultraviolet light strikes the surface of epoxy, it breaks certain carbon-hydrogen bonds. These newly freed atoms form reactive molecules called free radicals, which start attacking nearby polymer chains. The outcome is a slow, self-perpetuating cycle of molecular damage.

This degradation doesn’t just affect appearance; it also changes the epoxy’s physical properties. Over time, the surface may become more brittle or less flexible, particularly if no UV stabilizers were included in the formulation. Preventing photooxidation is thus key not only for maintaining color but also for preserving the coating’s mechanical integrity.

Free Radicals and Molecular Breakdown

Free radicals are unstable atoms seeking to bond with anything nearby. In epoxy floor coating, they react with oxygen, forming peroxides and other by-products that absorb visible yellow wavelengths of light. The more radicals produced, the deeper the discoloration. Heat and oxygen accelerate this process, making sunny or high-temperature environments more vulnerable.

HALS additives interrupt this chain reaction by “scavenging” free radicals before they can spread damage. This chemical defense system is one reason why modern epoxy coatings from specialists like GLI Epoxy Flooring last longer and stay clearer than older generations.

Real-World Conditions That Speed Up Discoloration

The rate at which epoxy floor coating yellows varies depending on environmental conditions. Outdoor installations face direct UV bombardment, while indoor floors experience reflected or artificial UV exposure. Knowing how different settings influence degradation helps in developing preventive strategies.

Even two floors installed with the same materials can age differently based on lighting, ventilation, and maintenance routines. Understanding these nuances helps ensure consistent color retention across all areas of a property.

Indoor vs. Outdoor Epoxy Applications

Outdoor epoxy systems experience the harshest conditions: direct sunlight, rain, and fluctuating temperatures. Without a UV-stable topcoat, they can begin to yellow within months. Indoor floors age more slowly but aren’t immune. In homes and commercial buildings, natural light streaming through large windows can cause gradual fading near the edges of sun-exposed rooms.

For Toronto property owners, where seasonal light intensity varies widely, this means adopting adaptable maintenance habits — such as applying clear sealants every few years and keeping blinds or shades drawn during peak daylight hours.

Industrial Lighting and UV Exposure

Industrial facilities often use high-intensity lamps like halogen or mercury vapor lights, both of which emit UV radiation. Continuous exposure to these sources can accelerate discoloration even in enclosed areas. Epoxy floors coating under such lighting may show uneven yellow patches directly beneath fixtures.

Switching to LED lighting dramatically reduces UV output, making it a practical way to extend epoxy clarity in warehouses, factories, and commercial garages. Combined with UV-resistant coatings, this approach creates an environment where color change is minimal even after years of use.

How to Prevent Epoxy Floor Coating from Yellowing

Prevention always starts with informed choices — from selecting the right materials to maintaining optimal conditions after installation. While yellowing can’t be completely eliminated, it can be slowed down so effectively that it becomes nearly unnoticeable for many years.

The following preventive measures rely on scientific principles that stop or delay the oxidation and photo-degradation processes that cause color change.

Choosing the Right UV-Stabilized Epoxy System

The most effective protection comes from using UV-stabilized epoxy coatings containing HALS and UV absorbers. These additives act as sunscreen for polymers, absorbing harmful energy and neutralizing free radicals before they can damage the resin. The result is a clear, stable surface that resists yellowing even under extended sunlight exposure.

At GLI Epoxy Flooring, advanced UV-resistant formulations are used for projects in areas like Toronto, where seasonal sunlight and heat are common. These modern systems provide the same gloss and hardness as traditional epoxy but maintain their transparency much longer.

Importance of Proper Installation Conditions

Even the best epoxy formula can fail if applied in poor conditions. High humidity, improper mixing ratios, or temperature extremes during curing can cause premature oxidation. Controlled environments ensure the resin cross-links correctly, forming a dense, uniform network that resists future chemical changes.

Maintaining stable airflow and avoiding moisture exposure during curing are key. Installers monitor temperature and humidity throughout the process, ensuring the surface cures evenly and develops its full resistance to environmental stress.

Routine Cleaning and Maintenance Practices

Regular cleaning extends the life and clarity of epoxy floor coating. The best approach is gentle — sweep or vacuum debris and clean with a mild, pH-neutral solution. Harsh detergents, ammonia, or bleach strip protective layers, allowing UV damage to penetrate more easily. Even something as simple as switching to non-abrasive microfiber mops can make a big difference over time.

Routine maintenance also includes checking for fine scratches or scuff marks, which can trap dirt and amplify the yellow tint. A quick buffing or re-sealing keeps the surface smooth and less reactive to light and oxygen

Using Protective Sealants for Longevity

Adding a polyurethane or polyaspartic topcoat creates an invisible barrier against sunlight and oxidation. These clear sealants absorb or reflect UV rays, reducing their intensity before they reach the epoxy layer below. The extra coating doesn’t just preserve color — it enhances gloss and makes cleaning easier.

Over time, reapplying a topcoat every few years helps refresh protection and extend lifespan. For areas with heavy UV exposure, such as garages or workshops with open doors, this step is one of the most effective long-term defenses against yellowing.

Scientific Advances in Non-Yellowing Epoxy Coatings

The coatings industry continues to innovate with materials that resist both UV light and heat. Modern epoxies incorporate nanoparticles that scatter light, preventing UV energy from penetrating deep into the polymer. These nanoceramic additives not only improve color stability but also enhance scratch resistance and surface hardness.

Another breakthrough involves “smart polymers” that adapt their molecular flexibility depending on temperature. By staying more elastic under heat, they resist cracking and photooxidation, further delaying yellowing. Such innovations are transforming how professionals design and maintain long-lasting, clear epoxy systems.

How GLI Epoxy Flooring Approaches Color Stability

With extensive experience in the field, GLI Epoxy Flooring emphasizes research-based techniques to enhance color retention and overall durability. The company uses advanced UV-resistant epoxy systems that combine chemical stabilizers, flexible topcoats, and careful curing processes to deliver consistent clarity across residential, commercial, and industrial projects.

Real-world tests show that floors installed under controlled conditions with these UV-resistant systems maintain over 95 percent clarity even after years of exposure. Continuous quality monitoring and field analysis allow GLI technicians to refine their methods further, ensuring that epoxy floor coating in diverse climates like Toronto remains visually pristine and structurally sound.

GLI Epoxy Flooring Serving the Elms-Old Rexdale and Beyond in Toronto

GLI Epoxy Flooring is dedicated to serving the diverse needs of the local community of Toronto, including individuals residing in neighborhood like Elms-Old Rexdale With its convenient location near landmarks such as the The Elms Park, Rexlington Park major intersections like Islington Ave & Shenandoah Dr and Burrard Rd & Sego Rd (coordinates: 43.720521,-79.553995), We offer Epoxy Floor Coating services.

Get Epoxy Floor Coating Services at Elms-Old Rexdale Now.

Navigate from Elms-Old Rexdale to GLI Epoxy Flooring

What Causes Epoxy Floor Coating to Yellow Over Time and How to Prevent It

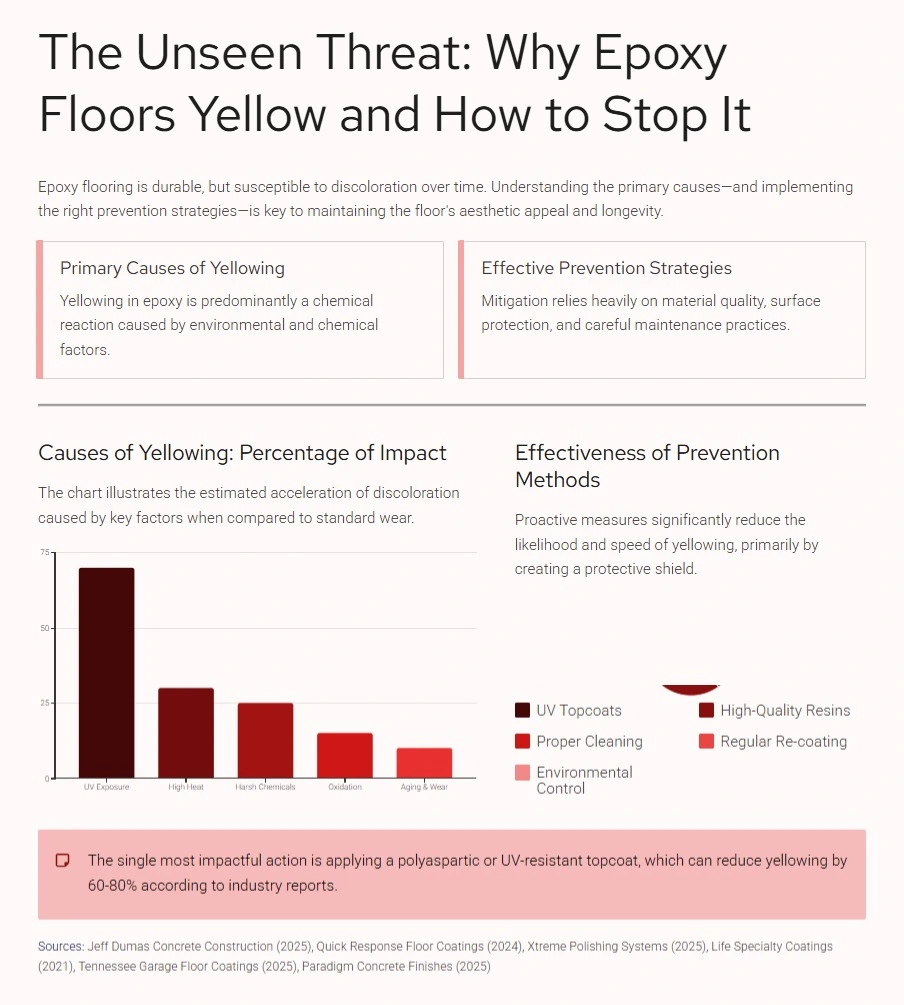

- Primary Causes of Yellowing:

- UV Exposure: Over 70% of yellowing cases linked to sunlight breaking down epoxy polymers (Jeff Dumas Concrete Construction, 2025)

- Heat: High temperatures accelerate chemical degradation, increasing yellowing risk by up to 30% in hot environments (Quick Response Floor Coatings, 2024)

- Chemical Damage: Use of ammonia or acidic cleaners can cause up to 25% faster discoloration (Tennessee Garage Floor Coatings, 2025)

- Aging & Wear: Natural polymer breakdown and wear cause gradual yellowing over 5+ years (Xtreme Polishing Systems, 2025)

- Oxidation of Hardeners: Exposure to air oxidizes hardeners, contributing to yellowing especially if stored improperly (Life Specialty Coatings, 2021)

- Effective Prevention Strategies:

- UV-Resistant Topcoats: Applying polyaspartic or UV-stabilized coatings reduces yellowing by 60-80% (Jeff Dumas Concrete Construction, 2025)

- High-Quality Epoxy Products: Premium resins with HALS additives slow yellowing onset by up to 50% (Xtreme Polishing Systems, 2025)

- Proper Cleaning: Avoid ammonia, acidic, and soap-based cleaners; use epoxy-safe products or water only (Jeff Dumas Concrete Construction, 2025)

- Environmental Controls: Limit direct sunlight exposure and maintain moderate temperatures to extend floor life (Tennessee Garage Floor Coatings, 2025)

- Regular Maintenance: Reapply protective topcoats every 2-3 years to maintain UV barrier and gloss (Paradigm Concrete Finishes, 2025)

Sources: Jeff Dumas Concrete Construction (2025), Quick Response Floor Coatings (2024), Xtreme Polishing Systems (2025), Life Specialty Coatings (2021), Tennessee Garage Floor Coatings (2025), Paradigm Concrete Finishes (2025)

Epoxy floor coating yellowing isn’t a flaw — it’s a natural chemical reaction between polymers, light, and air. The good news is that modern science offers reliable ways to control and slow it. By understanding the causes — UV radiation, oxidation, temperature, and environmental exposure — you can protect your floors for decades.

Using high-quality UV-stabilized epoxy systems, maintaining proper installation conditions, and following a consistent care routine will ensure your epoxy floor coating keeps its original clarity and professional finish. Knowledge and prevention are the best tools for maintaining beauty and performance in epoxy floor coating across Toronto and beyond.

FAQs

Does epoxy floor coating always turn yellow over time?

Most traditional epoxy floors will show some discoloration eventually, but modern UV-resistant formulations greatly reduce this effect.

Is yellowing only a cosmetic problem?

Yes. It typically affects appearance but not the strength or performance of the epoxy floor coating.

How can I prevent yellowing in high-sun areas?

Use UV-stabilized epoxy with a polyurethane topcoat and limit direct sunlight exposure where possible.

Can household cleaners cause yellowing?

Yes. Ammonia or acidic products can accelerate oxidation. Stick to mild, pH-neutral cleaners.

Is it possible to reverse yellowing once it occurs?

Unfortunately, no. The only effective fix is resurfacing or applying a new UV-resistant clear coat.